Compressor bearings are an important component of the compressor, and bearing wear can cause problems such as increased bearing clearance and unstable rotor. Bearing failure can lead to compressor shutdown and even serious accidents. Therefore, the maintenance and upkeep of compressor bearings is very important.

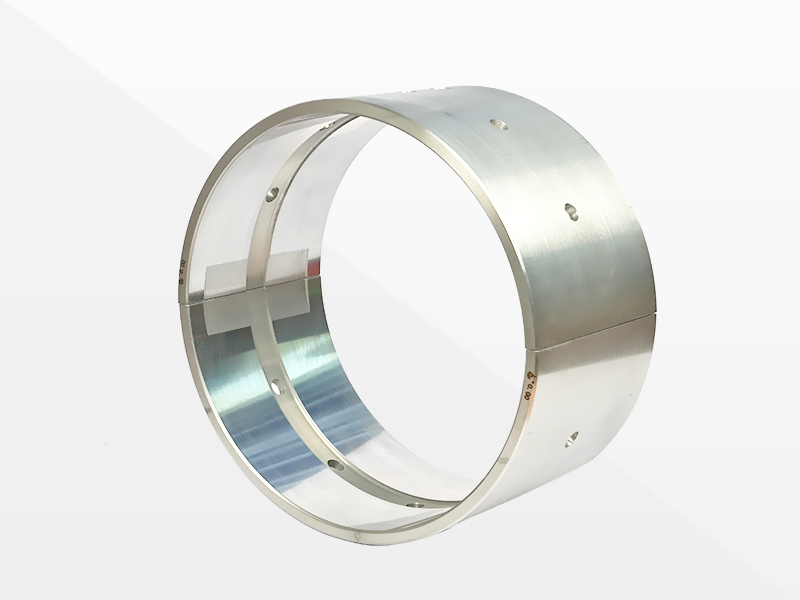

Zhongyuan Sliding Chaoshi Centrifugal Compressor Tilting Bearing

The daily maintenance of compressor bearings should pay attention to the following points:

1) Cleaning and lubrication: Regularly clean bearings and lubrication systems to remove dust, dirt, and other impurities.

2) Lubricating oil management: Check the quality and quantity of lubricating oil, and use and replace lubricating oil according to the manufacturer's recommendations.

3) Bearing clearance: Regularly check the bearing clearance to ensure it is within the appropriate range. Excessive or insufficient clearance may cause bearing failure.

4) Temperature and vibration monitoring: Regularly measure the temperature and vibration level of bearings; Abnormal temperature rise and excessive vibration may be indications of bearing failure. When abnormalities are detected, they should be promptly checked and necessary maintenance measures should be taken.

5) Regular inspection and replacement: Regularly check the degree of bearing wear; If obvious wear, damage or abnormal noise is found, the bearings should be replaced in a timely manner; It is recommended to replace according to the manufacturer's instructions to ensure proper matching and installation.

6) Avoid overload operation: Ensure that the compressor operates within the designed load range and avoid overload and overload operation.

7) Pay attention to the working environment: Keep the environment around the compressor clean and try to avoid dust, moisture, and chemical substances from entering.